Scaffolding Companies Wasco

Find the best Scaffolding Builders in Wasco

Get up to 3 Scaffolding Erectors quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best deal.

Designs plastering inc

41 reviewsOxnard, USDesigns Plastering, Inc. Agustin Espinoza, the owner of Designs Plastering, Inc., provides reliable, cost-effective, high-quality plastering and lathing services. Designs Plastering, Inc. serves the general public, working on both residential and commercial projects. The company is known for its courteous, professional, and punctual service. They are adept at handling smaller domestic jobs with the same expertise as larger contracts. Their reputation is built on quality. Based in Oxnard, CA, Designs Plastering, Inc. covers Santa Barbara, Ventura, and parts of Los Angeles counties and surrounding cities. For a free, no-obligation estimate or quotation, you can contact us HERE . Alternatively, call the office at: (805) 469-8395 for a quick response. Mission Statement At Designs Plastering, Inc., our mission is to deliver the highest quality finishing work for your exterior or plastering project. We utilize the latest tools and techniques available and employ only qualified personnel. Our work, as well as our workers, are fully insured. Our presence on your job site is professional, efficient, and easily coordinated with other trades.

- Services

- Why Us?

- Accreditations

- Our Team

- Gallery

Get Quote

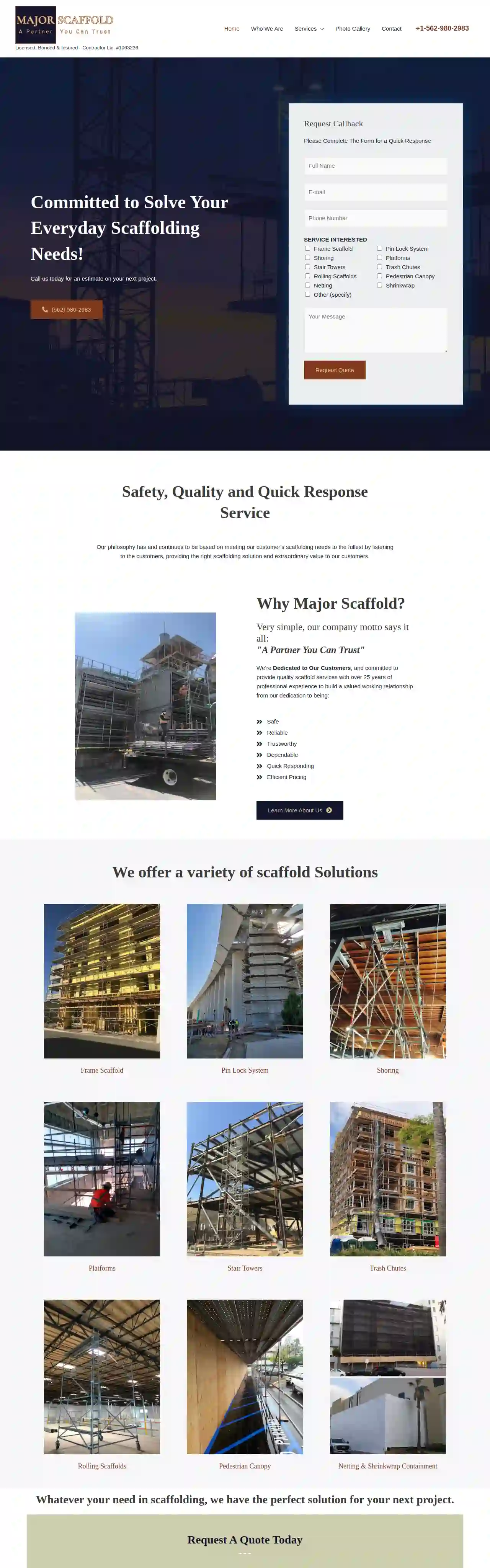

Major Scaffold, Inc.

55 reviews2908 E Hullett St, Long Beach, 90805, USMajor Scaffold, Inc. is a leading provider of scaffolding solutions in Southern California. With over 25 years of professional experience, the company is dedicated to providing quality services and building valued working relationships with its customers. Their commitment to safety, quality, and quick response service sets them apart from competitors. They offer a wide range of scaffolding solutions including frame scaffolds, pin lock systems, shoring, platforms, stair towers, rolling scaffolds, pedestrian canopies, netting containment, shrinkwrap containment, and trash chutes. Their team is experienced and dedicated to solving everyday scaffolding needs efficiently and effectively.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

- Gallery

Get Quote

INTEGRATED SCAFFOLDING CONCEPTS

54 reviews11924 Old Stage Road, Chester, 23836, USAt Integrated Scaffolding Concepts, we're your trusted partner in scaffolding excellence since 2015. Our seasoned team of professionals is unwavering in its commitment to delivering the pinnacle of scaffolding solutions tailored to your specific project requirements. We offer more than just scaffolding; we provide a solid foundation for your ambitions. Our adept engineers can craft a scaffold system that harmonizes seamlessly with the most demanding environments, ensuring a secure and reliable working platform for all your access needs. Our ethos revolves around a dual commitment: functionality and safety. These are paramount considerations not only during the setup phase but throughout the entire lifecycle of your project. We recognize that scaffolding is an indispensable asset, integral to every facet of your undertaking. Discover how ISC can elevate your scaffolding experience, setting a new standard for excellence and safety in your projects. Trust in our expertise and let us be your scaffolding partner of choice.

- Services

- Why Us?

- Our Team

- Gallery

Get Quote

BrandSafway Solutions Richmond

35 reviews123 Main St, Richmond, 23219, USAt BrandSafway, we are committed to providing innovative, safe, and efficient solutions to our customers in the Richmond area. With a strong focus on customer satisfaction, we offer a wide range of services, including scaffolding, forming and shoring, and industrial services. Our team of experts is dedicated to delivering exceptional results, and we take pride in our ability to adapt to the unique needs of each project. With a rich history dating back to 1919, BrandSafway has established itself as a leader in the access and industrial services industry. Our commitment to safety, quality, and customer satisfaction has earned us a reputation as a trusted partner for construction, industrial, and infrastructure projects.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

Get Quote

Power Scaffold Service

4.52 reviews157 East Terrance Way, Bakersfield, 93307, USAt Power Scaffold Services, we build long-lasting relationships with our clients by working closely with them to understand and anticipate their needs. We provide cost-effective solutions that enable our clients to complete their projects safely, on-time, and according to plan. Our top-notch, versatile team has erected and dismantled scaffolds for hospitals, theaters, restaurants, oil refineries, power plants, chemical plants, cement plants, and water treatment plants using our state of the art, long-lasting, and durable Cup-Lock Scaffold System.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

Elite Scaffold LLC

4.822 reviewsOakland, USAt Elite Scaffold, we are fully devoted to providing the best access solutions in Northern California. As a family operated business, we work by our values of safety, reliability and communication. With 25+ years of experience, we know these values lead to flawless execution of every project, every time. Our number one priority is protecting our clients, workers and the surrounding community. We have an impeccable safety record and are fully committed to keeping it this way. That’s why our elite team of riggers is highly trained in congruence with OSHA regulations. Our steadfast work ethic ensures that every project is done both efficiently and cost-effectively. We emphasize clear and consistent communication, so that our clients and the community have peace of mind every step of the way. We provide elite scaffolding services for your projects, including residential and commercial scaffolding, suspended platforms, access towers, engineered shoring, debris chutes, shrink wrap and netting, and pedestrian canopy.

- Services

- Why Us?

- Accreditations

- Testimonials

- Gallery

Get Quote

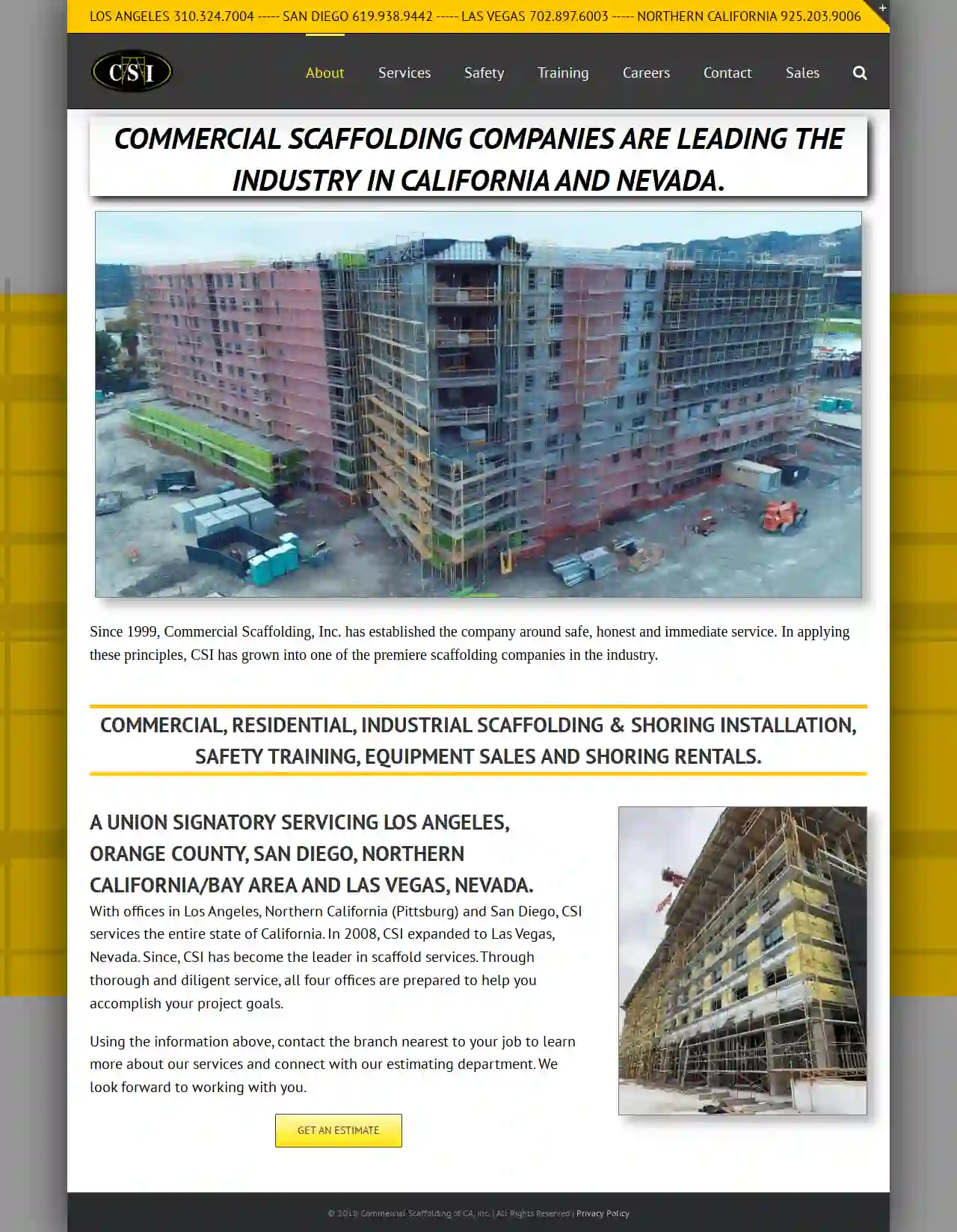

Commercial Scaffolding of CA, Inc.

4.54 reviewsLos Angeles, USAbout Commercial Scaffolding, Inc. Since 1999, Commercial Scaffolding, Inc. (CSI) has been a leading provider of scaffolding services in California and Nevada. We are committed to providing safe, honest, and immediate service to our clients. This commitment has allowed us to grow into one of the premier scaffolding companies in the industry. We offer a wide range of scaffolding and shoring services, including: Commercial scaffolding Residential scaffolding Industrial scaffolding Shoring installation Safety training Equipment sales Shoring rentals We are a union signatory and serve the following areas: Los Angeles Orange County San Diego Northern California/Bay Area Las Vegas, Nevada With offices in Los Angeles, Northern California (Pittsburg), and San Diego, CSI services the entire state of California. In 2008, CSI expanded to Las Vegas, Nevada. Since then, CSI has become the leader in scaffold services. Through thorough and diligent service, all four offices are prepared to help you accomplish your project goals. Contact the branch nearest to your job to learn more about our services and connect with our estimating department. We look forward to working with you.

- Services

- Why Us?

- Our Team

- Gallery

Get Quote

United Scaffold, Inc.

San Diego, USUnited Scaffold Inc. specializes in providing a wide range of scaffolding solutions, including frame scaffolding, modular scaffolding, and shrink wrap containment. They also offer temporary stairtower systems for safe and efficient egress to all levels and heights, conforming with Cal-OSHA's safety guidelines for emergency access. Additionally, they provide overhead protection canopy systems to ensure pedestrian and worker safety, and can assist in procuring traffic control and encroachment permits. Their steel and wood heavy-duty debris trash chutes are designed for moving materials efficiently and safely.

- Services

- Why Us?

- Gallery

Get Quote

A1 Equipment Rentals

4.927 reviews5809 E Brown Ave, Fresno, 93727, USWelcome to A1 Equipment Rentals, your #1 source for equipment and tool rentals, and supplies in Fresno, CA. Our goal is to provide our customers in the Central Valley with a great rental experience. We offer solutions for homeowners and contractors, and our family-owned and operated business has been serving the community since 2013. Our story began when Justin Priddy, our founder, worked as a manager at a small local equipment rental company for 13 years. When the owner decided to close the business overnight, Justin saw an opportunity to start his own rental yard that would cater to small businesses and homeowners. With the help of his parents, Bill and Jordan Priddy, A1 Equipment Rentals was established, and we've been growing ever since. We believe in building strong relationships with our customers, treating each person like family, and providing excellent customer service. Our team is dedicated to helping you rent the right equipment and tools you need to get the job done. Whether you're a professional contractor or a homeowner, we've got you covered.

- Services

- Why Us?

- Our Team

- Gallery

Get Quote

BrandSafway Services Sacramento

3.48 reviewsSacramento, CA, 123 Main St, 95814, USBrandSafway is a leading provider of access and scaffolding solutions in Sacramento, California. With a strong commitment to safety and customer satisfaction, we offer a wide range of services to meet the unique needs of our clients. From industrial and commercial construction to maintenance and repair, our team of experts is dedicated to delivering high-quality solutions that exceed expectations. At BrandSafway, we pride ourselves on our ability to provide innovative and cost-effective solutions that meet the evolving needs of our clients. Our team of experienced professionals is dedicated to ensuring that every project is completed safely, on time, and within budget. Whether you're looking for scaffolding, hoisting, or other access solutions, we have the expertise and resources to get the job done right.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

Get Quote

Over 2,353+ Scaffolding Companies registered

Our scaffolding companies operate in Wasco & surroundings!

ScaffoldingHQ has curated and vetted the Best Scaffolding Businesses near Wasco. Find a top & trustworthy contractor today.

Frequently Asked Questions About Scaffolding Companies

- Experience: 'How long have you been in business, and what experience do you have with projects like mine?'

- Licensing and Insurance: 'Are you fully licensed and insured, and can I see proof of coverage?'

- Safety Record: 'What are your safety procedures, and how do you ensure worker safety on the job site?'

- References: 'Can you provide references from previous clients?'

- Quotes and Costs: 'Can you provide a detailed quote that outlines all costs, including materials, labor, and any additional services?'

- Project Timeline: 'What is the estimated timeframe for scaffolding erection and dismantling?'

- Communication: 'How will you communicate with me throughout the project?'

- Tube and Clamp Scaffolding: A traditional and versatile system using individual tubes and clamps. It's highly adaptable but requires more time to erect.

- System Scaffolding: Pre-engineered systems with modular components that fit together quickly. They offer speed and efficiency, especially for larger projects.

- Suspended Scaffolding: Hung from a roof or overhead structure, ideal for high-rise buildings or areas with limited ground access.

- Mobile Scaffolding: Mounted on wheels, allowing easy movement around a worksite. Suitable for tasks like painting or plastering.

- Specialized Scaffolding: Cantilever scaffolding, rolling towers, and other specialized systems cater to specific needs.

- Falls from Height: The most significant risk, often due to lack of guardrails, improper use of safety harnesses, or unstable platforms.

- Falling Objects: Tools, materials, or debris falling from the scaffolding can injure workers or people below.

- Scaffold Collapse: Improper assembly, overloading, or inadequate foundation support can lead to a catastrophic collapse.

- Electrocution: Contact with overhead power lines is a serious hazard when working near electrical infrastructure.

- Slips, Trips, and Falls: Wet or cluttered platforms, uneven surfaces, and loose debris can cause falls.

- A larger, more complex structure typically used for accessing multiple levels of a building.

- Offers greater height and versatility.

- Often used for construction, renovation, and maintenance.

- Smaller, portable platforms usually used for tasks at a single level.

- Commonly used for painting, plastering, or light repairs.

- Can be rolling or stationary.

What questions should I ask a scaffolding company before hiring them?

What are the different types of scaffolding?

What are some common scaffolding safety hazards?

What is the difference between scaffolding and staging?

Scaffolding:

What questions should I ask a scaffolding company before hiring them?

- Experience: 'How long have you been in business, and what experience do you have with projects like mine?'

- Licensing and Insurance: 'Are you fully licensed and insured, and can I see proof of coverage?'

- Safety Record: 'What are your safety procedures, and how do you ensure worker safety on the job site?'

- References: 'Can you provide references from previous clients?'

- Quotes and Costs: 'Can you provide a detailed quote that outlines all costs, including materials, labor, and any additional services?'

- Project Timeline: 'What is the estimated timeframe for scaffolding erection and dismantling?'

- Communication: 'How will you communicate with me throughout the project?'

What are the different types of scaffolding?

- Tube and Clamp Scaffolding: A traditional and versatile system using individual tubes and clamps. It's highly adaptable but requires more time to erect.

- System Scaffolding: Pre-engineered systems with modular components that fit together quickly. They offer speed and efficiency, especially for larger projects.

- Suspended Scaffolding: Hung from a roof or overhead structure, ideal for high-rise buildings or areas with limited ground access.

- Mobile Scaffolding: Mounted on wheels, allowing easy movement around a worksite. Suitable for tasks like painting or plastering.

- Specialized Scaffolding: Cantilever scaffolding, rolling towers, and other specialized systems cater to specific needs.

What are some common scaffolding safety hazards?

- Falls from Height: The most significant risk, often due to lack of guardrails, improper use of safety harnesses, or unstable platforms.

- Falling Objects: Tools, materials, or debris falling from the scaffolding can injure workers or people below.

- Scaffold Collapse: Improper assembly, overloading, or inadequate foundation support can lead to a catastrophic collapse.

- Electrocution: Contact with overhead power lines is a serious hazard when working near electrical infrastructure.

- Slips, Trips, and Falls: Wet or cluttered platforms, uneven surfaces, and loose debris can cause falls.

What is the difference between scaffolding and staging?

Scaffolding:

- A larger, more complex structure typically used for accessing multiple levels of a building.

- Offers greater height and versatility.

- Often used for construction, renovation, and maintenance.

- Smaller, portable platforms usually used for tasks at a single level.

- Commonly used for painting, plastering, or light repairs.

- Can be rolling or stationary.