Scaffolding Companies Monrovia

Top Scaffolding Erectors in Monrovia

Get multiple Scaffolding Company quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best offer.

PCI Scaffold & Insulation

3.65 reviews123 Main St, Springfield, IL, 12345, USPerformance Contracting, Inc. is a leading specialty contractor in the United States, offering a wide range of services and solutions tailored to the specific needs of diverse market sectors. With over 60 years of industry experience, PCI delivers top-tier construction services, focusing on minimizing hand-offs and delays between craft workers and subcontractors to improve work efficiencies and scheduling. PCI's integrated service offerings provide a comprehensive solution designed to streamline projects and increase overall efficiency.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

- Gallery

Get Quote

Designs plastering inc

41 reviewsOxnard, USDesigns Plastering, Inc. Agustin Espinoza, the owner of Designs Plastering, Inc., provides reliable, cost-effective, high-quality plastering and lathing services. Designs Plastering, Inc. serves the general public, working on both residential and commercial projects. The company is known for its courteous, professional, and punctual service. They are adept at handling smaller domestic jobs with the same expertise as larger contracts. Their reputation is built on quality. Based in Oxnard, CA, Designs Plastering, Inc. covers Santa Barbara, Ventura, and parts of Los Angeles counties and surrounding cities. For a free, no-obligation estimate or quotation, you can contact us HERE . Alternatively, call the office at: (805) 469-8395 for a quick response. Mission Statement At Designs Plastering, Inc., our mission is to deliver the highest quality finishing work for your exterior or plastering project. We utilize the latest tools and techniques available and employ only qualified personnel. Our work, as well as our workers, are fully insured. Our presence on your job site is professional, efficient, and easily coordinated with other trades.

- Services

- Why Us?

- Accreditations

- Our Team

- Gallery

Get Quote

BrandSafway

3.56 reviewsVallejo, USPlatinum Scaffolding Services: Your Trusted Partner for Safe and Reliable Scaffolding Solutions Platinum Scaffolding Services is a leading provider of high-quality scaffolding solutions for a wide range of projects. We are committed to providing our clients with safe, reliable, and efficient scaffolding services that meet their specific needs. Our team of experienced professionals is dedicated to delivering exceptional customer service and exceeding expectations. Our Services At Platinum Scaffolding Services, we offer a comprehensive range of scaffolding services to meet the diverse needs of our clients. Our services include: Scaffolding Design and Installation Scaffolding Inspection and Maintenance Scaffolding Removal and Dismantling Scaffolding Rental Why Choose Platinum Scaffolding Services? We are committed to providing our clients with the highest quality scaffolding services. Our team of experienced professionals is dedicated to delivering exceptional customer service and exceeding expectations. We are also committed to safety and compliance, ensuring that all of our projects are completed to the highest standards. Experienced and Qualified Professionals Competitive Pricing Commitment to Safety and Compliance Exceptional Customer Service

- Services

- Why Us?

Get Quote

Power Scaffold Service

4.52 reviews157 East Terrance Way, Bakersfield, 93307, USAt Power Scaffold Services, we build long-lasting relationships with our clients by working closely with them to understand and anticipate their needs. We provide cost-effective solutions that enable our clients to complete their projects safely, on-time, and according to plan. Our top-notch, versatile team has erected and dismantled scaffolds for hospitals, theaters, restaurants, oil refineries, power plants, chemical plants, cement plants, and water treatment plants using our state of the art, long-lasting, and durable Cup-Lock Scaffold System.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

Ready Equipment Rental Inc.

421 reviews3969 N Sierra Way, San Bernardino, 92405, USAt Ready Equipment Rental, we have been providing our customers in the greater San Bernardino - Riverside Counties with an extensive variety of quality equipment rentals and tool rentals since 1988. From floor sanders to tile saws, utility trailers to tillers, tractors and bobcats to pressure washer's, we have the rental equipment and tools you need to build, maintain, power, move, or clean your projects. We are family owned, conveniently located at 3969 N Sierra Way, in San Bernardino Just north of the 210 Freeway and Waterman ave. We are here to help anyway we can for all your equipment rental and tool rental needs. Ask us about our affordable delivery and pickup, new and used equipment for sale.

- Services

- Why Us?

- Gallery

Get Quote

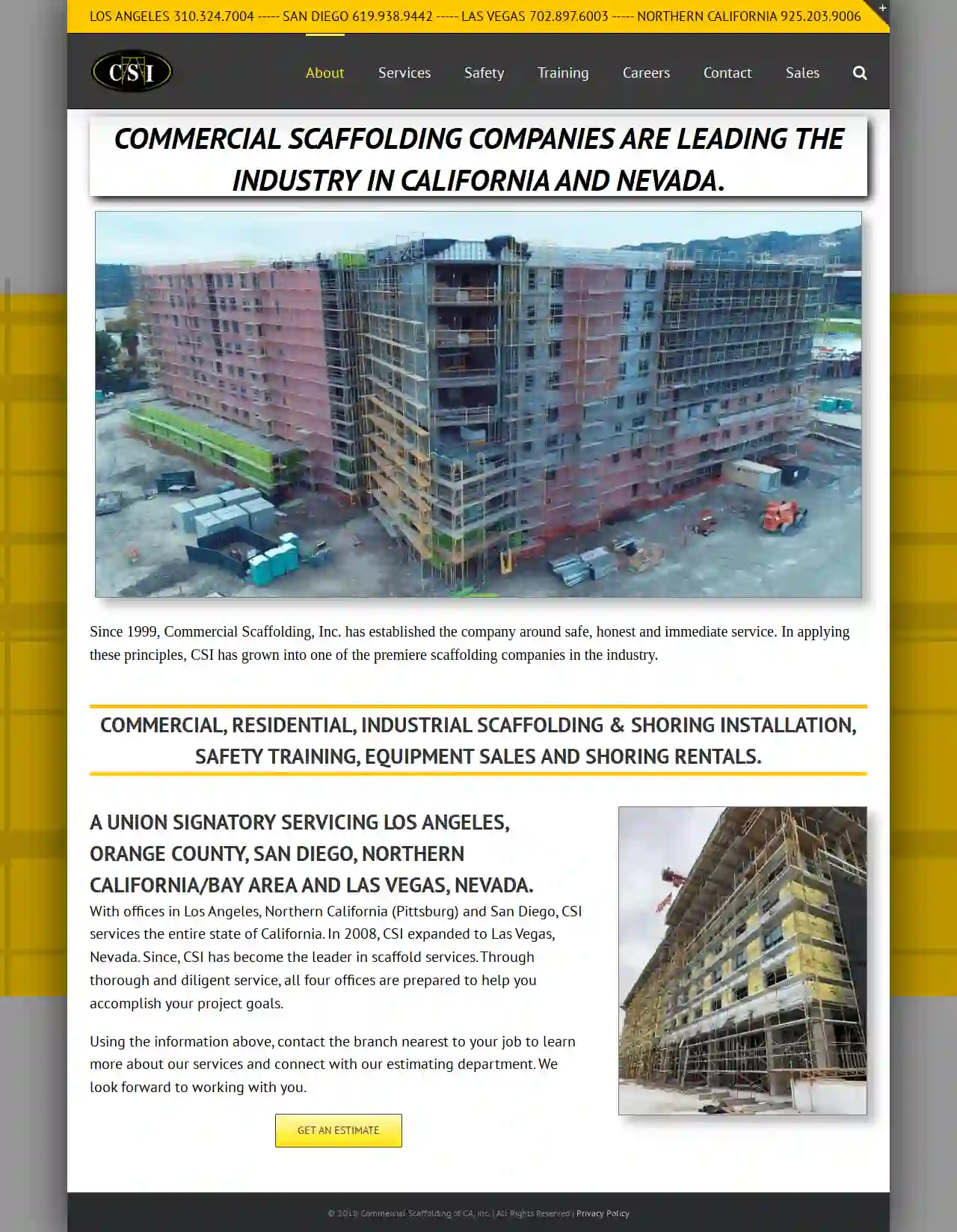

Commercial Scaffolding of CA, Inc.

4.54 reviewsLos Angeles, USAbout Commercial Scaffolding, Inc. Since 1999, Commercial Scaffolding, Inc. (CSI) has been a leading provider of scaffolding services in California and Nevada. We are committed to providing safe, honest, and immediate service to our clients. This commitment has allowed us to grow into one of the premier scaffolding companies in the industry. We offer a wide range of scaffolding and shoring services, including: Commercial scaffolding Residential scaffolding Industrial scaffolding Shoring installation Safety training Equipment sales Shoring rentals We are a union signatory and serve the following areas: Los Angeles Orange County San Diego Northern California/Bay Area Las Vegas, Nevada With offices in Los Angeles, Northern California (Pittsburg), and San Diego, CSI services the entire state of California. In 2008, CSI expanded to Las Vegas, Nevada. Since then, CSI has become the leader in scaffold services. Through thorough and diligent service, all four offices are prepared to help you accomplish your project goals. Contact the branch nearest to your job to learn more about our services and connect with our estimating department. We look forward to working with you.

- Services

- Why Us?

- Our Team

- Gallery

Get Quote

D L Scaffolding Inc

54 reviewsSan Rafael, USAt DL Scaffolding Inc, we provide safe, high-quality, and timely scaffold services to our clients in the San Francisco Bay Area and beyond. With a strong focus on trust, integrity, dependability, efficiency, detail-orientedness, and timeliness, we strive to deliver exceptional results that meet our clients' specific project needs. Our team of experts offers a range of services, including scaffold design and planning, scaffold erection, scaffold dismantling, scaffold rental, deliver and pick-up, and project management. We take pride in our ability to provide end-to-end scaffold services that ensure on-time completion and adherence to safety standards.

- Services

- Why Us?

- Gallery

Get Quote

Orange County Scaffold Inc

3.29 reviews121 E. Meats Ave., Orange, 92865, USOC Scaffold is a leading Southern California scaffold provider with unparalleled expertise in the industrial, commercial, residential, and infrastructure sectors. For over 50 years, our family-owned business has built strong relationships within the industry, handling projects ranging from small-scale to multi-million dollar ventures. We specialize in delivering innovative scaffolding solutions, temporary access and egress, and industrial services, tailored to meet the unique needs of each project. Collaborating closely with architects, engineers, and construction professionals, we ensure flexibility, safety, and efficiency in every task. At OC Scaffold, we're more than just a service provider; we're your trusted partner in building success.

- Services

- Why Us?

- Our Team

- Testimonials

- Gallery

Get Quote

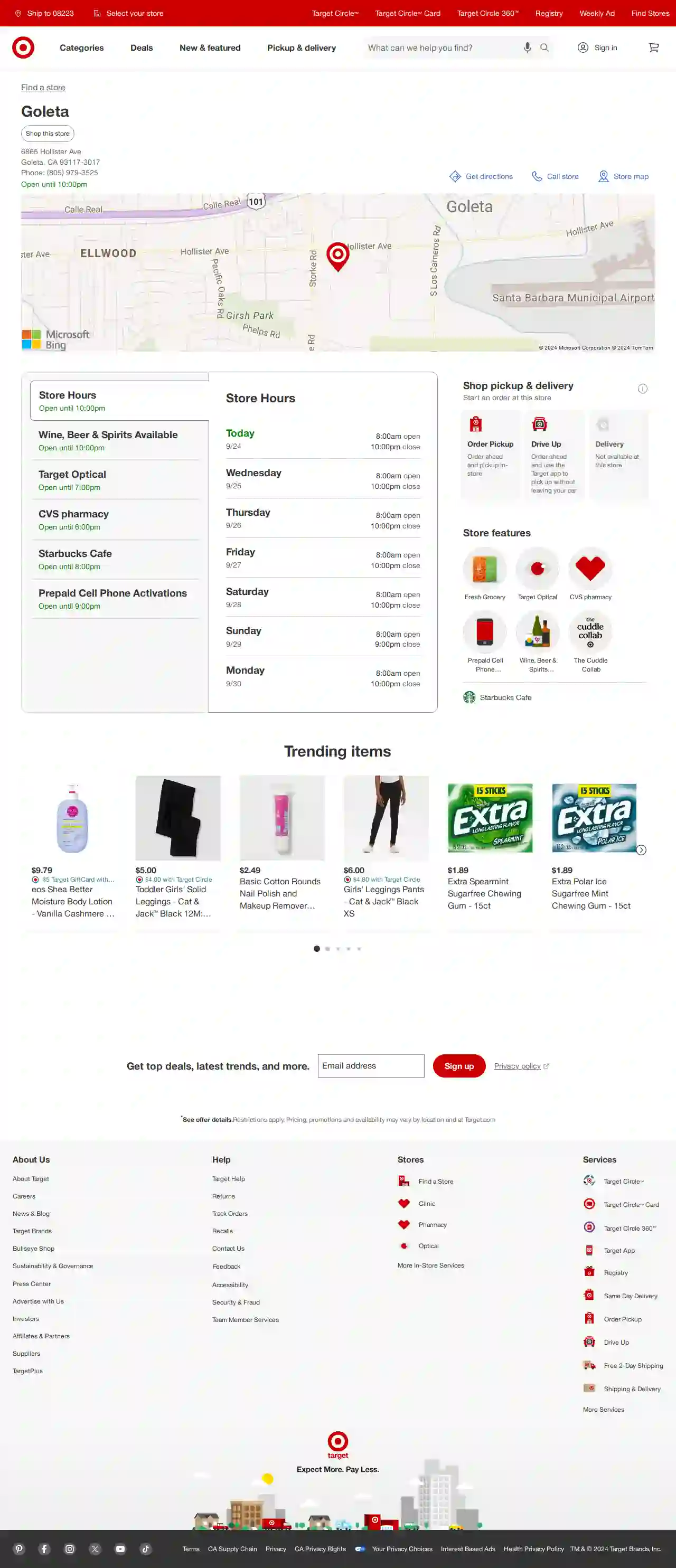

Target

3.5135 reviews6865 Hollister Ave, Goleta, 93117-3017, USTarget is a general merchandise retailer that offers a wide range of products, including clothing, electronics, home goods, and more. They have a strong focus on providing excellent customer service and a convenient shopping experience. With a presence in many locations across the US, Target is a popular destination for both online and in-store shopping. Their commitment to quality, value, and convenience has made them a trusted brand for many consumers.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

- Gallery

Get Quote

Contractors Scaffold Supply

4.84 reviews229 Harbor Way, South San Francisco, 94080-6811, USWelcome to Contractor's Scaffold Supply, Inc. Contractors Scaffold is a family owned company serving the greater San Francisco Bay Area, providing stationary scaffolding for residential and commercial use. We provide rental solutions for new or existing structures, drawing on our extensive knowledge and experience. Many of our crew members possess 10-15 years of experience in the field. Contractor's Scaffold can furnish, erect, and dismantle full scaffolding for our customers. You can relax knowing your scaffolding will be erected properly, safely, on-time, and in compliance with OSHA regulations. We also offer scaffolding components "rental or purchase" for customers who prefer to perform their own installations. Contractors Scaffold is also proud to have designed and patented a new safer All Thread Anchor Clamp. Find out more

- Services

- Why Us?

- Our Team

- Testimonials

- Gallery

Get Quote

Over 2,353+ Scaffolding Companies registered

Our scaffolding contractors operate in Monrovia and surrounding areas!

ScaffoldingHQ has curated and vetted Top Scaffolding Contractors near Monrovia. Find a trustworthy contractor today.

Frequently Asked Questions About Scaffolding Companies

- Encroaches onto public property (sidewalks, roads): Permits are usually needed from the local council or highway authority.

- Exceeds a certain height: Scaffolding above a specified height often requires a permit.

- Is erected in a conservation area or near a listed building: Special considerations and permits may apply.

- Traditional and highly versatile.

- Components (tubes, clamps, boards) are assembled on-site.

- Adaptable to complex shapes and structures.

- Requires skilled labor and more time for erection.

- Pre-engineered, modular components.

- Faster and easier to erect.

- Often has higher load capacities.

- May be less versatile for complex shapes.

- Regulations: Local regulations often specify minimum inspection intervals.

- Project Type and Duration: Long-term projects or those in challenging environments may require more frequent inspections.

- Weather Conditions: Severe weather (storms, high winds) can necessitate additional inspections.

- Any Alterations or Modifications: Any changes to the scaffolding structure require re-inspection.

- Project Height and Access: The height of the structure and the accessibility of the working area are primary considerations.

- Load Capacity: The weight of workers, materials, and equipment that the scaffolding needs to support.

- Project Complexity and Shape: The shape and complexity of the structure may necessitate specialized scaffolding configurations.

- Ground Conditions: The type of ground (soft, uneven, sloping) will influence the scaffolding foundation and support requirements.

- Duration of Use: The length of time the scaffolding will be needed can impact the choice of system.

- Budget: Different scaffolding types have varying costs.

Do I need a permit for scaffolding in the USA?

What is the difference between tube and clamp scaffolding and system scaffolding?

Tube and Clamp Scaffolding:

How often should scaffolding be inspected?

How do I choose the right type of scaffolding for my project?

Do I need a permit for scaffolding in the USA?

- Encroaches onto public property (sidewalks, roads): Permits are usually needed from the local council or highway authority.

- Exceeds a certain height: Scaffolding above a specified height often requires a permit.

- Is erected in a conservation area or near a listed building: Special considerations and permits may apply.

What is the difference between tube and clamp scaffolding and system scaffolding?

Tube and Clamp Scaffolding:

- Traditional and highly versatile.

- Components (tubes, clamps, boards) are assembled on-site.

- Adaptable to complex shapes and structures.

- Requires skilled labor and more time for erection.

- Pre-engineered, modular components.

- Faster and easier to erect.

- Often has higher load capacities.

- May be less versatile for complex shapes.

How often should scaffolding be inspected?

- Regulations: Local regulations often specify minimum inspection intervals.

- Project Type and Duration: Long-term projects or those in challenging environments may require more frequent inspections.

- Weather Conditions: Severe weather (storms, high winds) can necessitate additional inspections.

- Any Alterations or Modifications: Any changes to the scaffolding structure require re-inspection.

How do I choose the right type of scaffolding for my project?

- Project Height and Access: The height of the structure and the accessibility of the working area are primary considerations.

- Load Capacity: The weight of workers, materials, and equipment that the scaffolding needs to support.

- Project Complexity and Shape: The shape and complexity of the structure may necessitate specialized scaffolding configurations.

- Ground Conditions: The type of ground (soft, uneven, sloping) will influence the scaffolding foundation and support requirements.

- Duration of Use: The length of time the scaffolding will be needed can impact the choice of system.

- Budget: Different scaffolding types have varying costs.