Scaffolding Companies Bangor

Find Scaffolding Experts in Bangor

Get 3 FREE Scaffolding Companies quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best service.

New York Ladder & Scaffold Corporation

46 reviews122 Woodworth Ave, Yonkers, 10701, USWelcome to New York Ladder & Scaffolding Corporation, one of the oldest, family-owned-and-operated scaffolding companies in the country. With more than 120 years of experience, we have the experts on staff to help you with your project. Whether you are a large-scale project management company or a small business with a code violation, New York Ladder & Scaffolding has the solution and expertise to get the job done quickly and safely. We offer a full line of quality scaffolding available for rental, or purchase and installation. Our services include sidewalk sheds/sidewalk bridges, debris netting, trash/debris chutes, fence installations, rolling towers, stationary towers, swing stage scaffolding, masonry scaffolding/steel frame scaffolds, suspended scaffolding, electrical, manual and rope scaffolding. We continue to be a leader in erecting and dismantling scaffolding for general contractors, construction companies and small businesses in a safe and timely manner. Our hours of operation are Monday - Friday: 7:00 a.m. - 5:00 p.m. Contact our scaffolding company in Yonkers, New York, to request a ladder rental for your project.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

York Equipment Corp.

4.628 reviewsLong Island City, NY, 37-20 12th Street, 11101, USYork Scaffold Equipment Corp. has been serving New York City and the Metropolitan Area since 1928. The company specializes in providing a wide range of scaffolding solutions, including supported, suspended, and system scaffolds, as well as ladders, accessories, and safety equipment. With a strong commitment to customer satisfaction and safety, York Scaffold Equipment Corp. offers top-quality products and services to meet the needs of construction and renovation projects.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

- Gallery

Get Quote

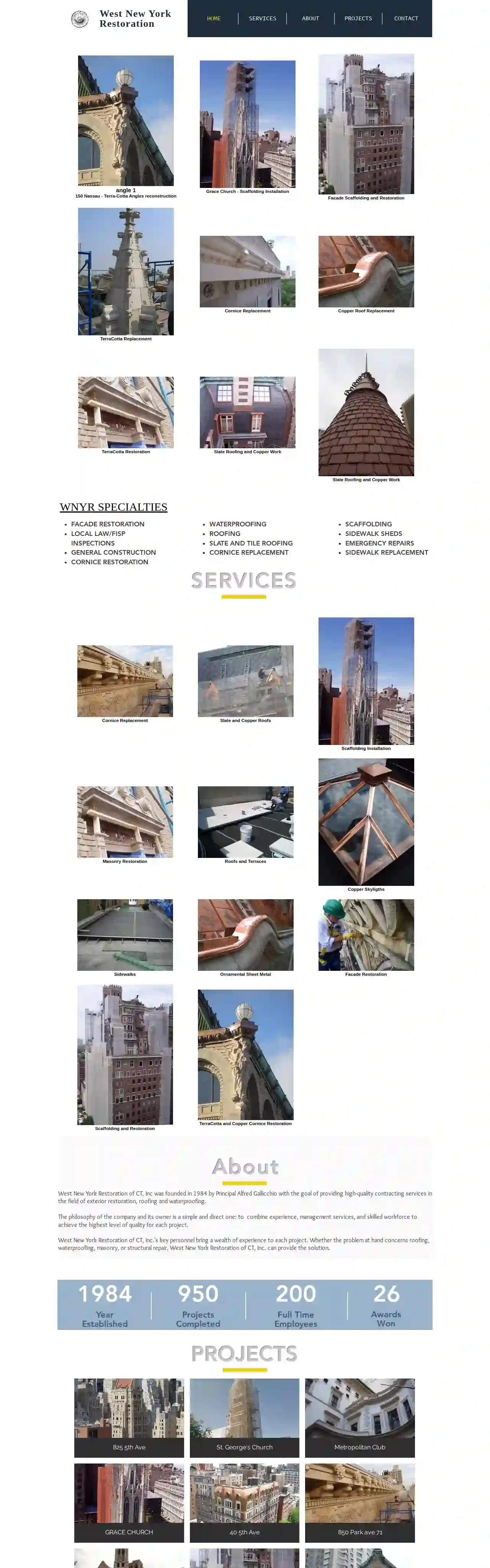

West New York Restoration of CT, INC

4.512 reviews1800 Boston Rd, Bronx, 10460, USWest New York Restoration of CT, Inc was founded in 1984 by Principal Alfred Gallicchio with the goal of providing high-quality contracting services in the field of exterior restoration, roofing and waterproofing. The philosophy of the company and its owner is a simple and direct one: to combine experience, management services, and skilled workforce to achieve the highest level of quality for each project. West New York Restoration of CT, Inc.'s key personnel bring a wealth of experience to each project. Whether the problem at hand concerns roofing, waterproofing, masonry, or structural repair, West New York Restoration of CT, Inc. can provide the solution.

- Services

- Why Us?

- Our Team

- Gallery

Get Quote

Keystone Sidewalk Shed & Scaffolding NYC

526 reviewsNew York City, USAt Keystone Sidewalk Shed & Scaffolding, we are dedicated to providing top-quality sidewalk shed and scaffolding solutions in New York City. Our commitment to safety, efficiency, and excellence sets us apart from the rest. With over 20 years of experience, we have successfully handled numerous projects, ensuring the safety of workers and pedestrians alike. Our team consists of DOB and OSHA-certified experts who are renowned for erecting high-capacity structures that comply with OSHA regulations. We offer a wide range of services including scaffolding rental, sidewalk shed rental, Jersey barriers rental, temporary fencing rental, and rigging services. Our commitment to safety has earned us prestigious awards, making us the trusted choice for diverse project needs.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

- Gallery

Get Quote

Dynamic Hoisting & Scaffolding

54 reviews43-30 48th St, Long Island City, 11104, USAt Dynamic Hoisting & Scaffolding, we transform your vision into reality with our expertise in hoisting and scaffolding solutions. Our team is dedicated to delivering exceptional results, ensuring your projects are completed on time and within budget. Established in 2013, Dynamic Hoisting & Scaffolding is dedicated to providing high-quality construction services that exceed our clients' expectations. Our mission is to innovate, sustain, and continually improve every aspect of our work. Join us in transforming the construction landscape with our reliable scaffolding solutions. We use the highest quality materials and craftsmanship to ensure durability and excellence in every project. We conduct our business with transparency, honesty, and respect, prioritize the safety of our employees, clients, and the community, and embrace new technologies and methods to enhance efficiency and effectiveness.

- Services

- Why Us?

- Testimonials

- Gallery

Get Quote

NYC Sidewalk Shed & Pipe Scaffolding

51 reviews1078 Arnow Ave, Bronx, NY, USAbout NYC Sidewalk Shed & Pipe Scaffolding NYC Sidewalk Shed & Pipe Scaffolding is the most trusted provider of premium quality sidewalk sheds and pipe scaffolding in NYC. We are the leading pipe scaffolding and sidewalk erector company, providing services in the whole of NYC. As a result of 20+ years of experience in the industry, we have become adept in providing high-quality sidewalk sheds and pipe scaffoldings consistently earning the satisfaction of all our clients. Our Mission At NYC, our mission is to provide excellent sidewalk shed and scaffolding services at extremely affordable rates. Hence, providing quality and safety that’s within everyone’s’ reach. From modern equipment to the best professionals, we try to cater to you with the best in every aspect. We aim to completely redefine what is possible in the construction industry by setting new standards for safety, efficiency, and innovation. Why Choose Us Providing you with high-quality solutions for all your problems is our foremost concern. We work with skilled professionals that have years of experience in dealing with sidewalk sheds and pipe scaffoldings. Besides, we make sure to use the best quality material sourced from the best manufactures. Hence, ensuring you quality structures that can withstand the test of time. Duralbes and Safe Structures We design safe and reliable pipe scaffoldings and sidewalk structures that can easily support the desired load. These structures will be stable and robust ensuring safety for everyone. Moreover, we assure compliance with both local and international safety codes, ensuring the complete safety of pedestrians and site workers from all sorts of accidents.

- Services

- Why Us?

- Gallery

Get Quote

NY Scaffold

51 reviewsYork, USWe are national scaffold contractors and scaffolding erectors. Experienced NY Scaffold erectors can provide a range of access services for you or your clients, we also take care of any and all NYC DOB Permits. Large and small projects; industrial, commercial and domestic sectors can hire the services of NY Scaffold erectors. No job is too big or too small for us and we have grown our business in the last few years to become one of the leading erectors of scaffolding and sidewalk bridges in the NYC area. Plan your project with complete confidence the sidewalk bridge company NYC can erect scaffolding to all types of structures. NYC installs scaffolds from access towers to bridges and any other type of access equipment that your firm might require. It does not matter how big or how small your project is NY scaffold company NYC will cater to your needs. They have secure access equipment that is perfect for projects in and around the region. Our Scaffolding has several unique safety features that benefit the system’s erectors, users and project inspectors. With eight completely variable component node points and the largest available bay sizes, Our Scaffolding offers the most flexible system. Only five main components are required for basic use and the only erection tools required are a hammer and level. The system’s optimum design offers a high load rating and extreme rigidity, keeping your workers secure and productive. NY Scaffold is the leading specialty Scaffold Erector Company covering the whole of the US. We are totally focused on customer satisfaction and pride ourselves on the range of services we provide, We have 95% repeat business on an ongoing basis. NY Scaffold is fully self-sufficient and one the largest stockholders of the sidewalk bridge system within the US. This forms the basis of the NY Scaffolds motto safety speed efficiency. Our business is based around the materials that are stored in bins and are loaded by forklift in our yards and unloaded on site by our Truck mounted Booms. We deliver our scaffolding equipment to your site, and our team of experienced erectors will set it up for you, ensuring that your project is completed safely and efficiently.

- Services

- Why Us?

- Gallery

Get Quote

BrandSafway Industries

123 BrandSafway Blvd, Swedesboro, 12345, USBrandSafway is a leading provider of access solutions, including scaffolding, aerial work platforms, and forming and shoring. With a strong commitment to safety, quality, and customer satisfaction, BrandSafway offers a wide range of services tailored to meet the unique needs of clients across various industries. Their team of experienced professionals works closely with clients to understand their requirements and deliver customized solutions that enhance efficiency and productivity. BrandSafway is dedicated to providing innovative access solutions that ensure safe and efficient project execution.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

Get Quote

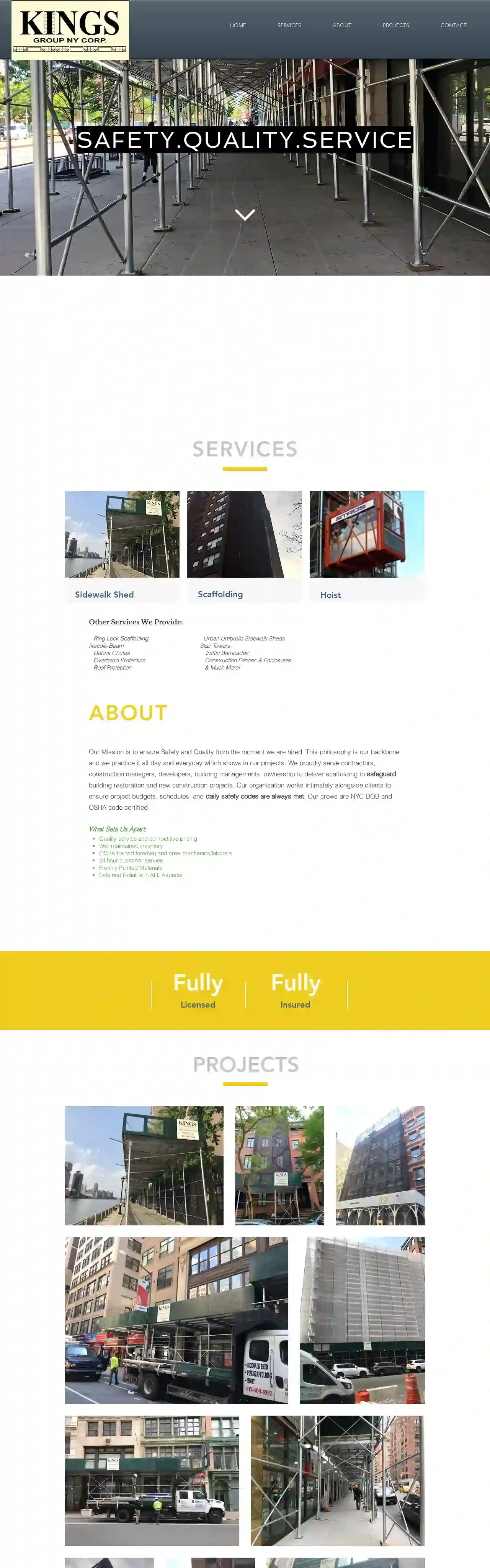

Kings Group NY Corp

51 reviews120-5 Atlantic Ave, Suite #2, Richmond Hill, 11418, USAt Kings Group NY, we prioritize Safety and Quality in every project we undertake. Our mission is to ensure that our clients receive the best possible service, from the initial consultation to the completion of the project. With a team of experienced professionals, we provide top-notch scaffolding services to contractors, construction managers, developers, and building owners. Our organization is committed to meeting project budgets, schedules, and daily safety codes, and we take pride in our ability to deliver exceptional results. Our team is comprised of NYC DOB and OSHA code-certified professionals who are dedicated to providing the highest level of service. We offer a range of services, including sidewalk sheds, scaffolding, hoists, and other specialized services. Our goal is to provide our clients with the best possible experience, and we strive to exceed their expectations in every way.

- Services

- Why Us?

- Accreditations

- Gallery

Get Quote

StepUp Scaffolding Warehouse - NY Branch

4.426 reviews1234 NW 12th St, Miami, 33122, USStepup Scaffold, a division of Sunshine Enterprises, started in 1998 and quickly became one of the largest importers and manufacturers of scaffolding and access equipment in the North American market. Our commitment to Quality, Service, and Satisfaction influences everything we do. We believe that a high tide raises all boats, so to raise everything and everyone, our statement of purpose, simply put is that “We elevate our employees, customers, and industries to safely move, build, and maintain the world.”

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

- Gallery

Get Quote

Over 2,353+ Scaffolding Companies on our directory

Our scaffolding companies operate in Bangor and surrounding areas!

ScaffoldingHQ has curated and vetted Top Scaffolding Companies near Bangor. Find the most trustworthy contractor today.

Frequently Asked Questions About Scaffolding Companies

- Size and Complexity: Larger, more intricate scaffolding structures will naturally take longer to assemble.

- Scaffolding Type: System scaffolding, with its pre-engineered components, can be erected faster than traditional tube and clamp scaffolding.

- Accessibility: Difficult site access or limited working space can prolong the erection process.

- Crew Size and Experience: The number and skill level of the scaffolding erectors will impact the speed of assembly.

- Always Wear a Safety Harness: Connect your harness to a secure anchor point at all times to prevent falls.

- Keep Platforms Clear: Remove tools, materials, and debris to avoid tripping hazards.

- Never Overload the Scaffolding: Stay within the designated weight limits.

- Be Aware of Your Surroundings: Pay attention to power lines, moving equipment, and other potential hazards.

- Inspect Before Use: Check the scaffolding for any damage or defects before starting work.

- Communicate Clearly: Use hand signals and clear communication to coordinate with other workers.

- Follow Safety Training: Attend and understand all safety training provided by your employer or the scaffolding company.

- Work at Height Regulations 2005: Covers all work at height and outlines the need for risk assessments, competent erectors, and safe equipment.

- Construction (Design and Management) Regulations 2015 (CDM): Applies to construction projects and requires planning for scaffolding safety throughout the project lifecycle.

- British Standard BS EN 12811: Sets standards for the design, manufacture, and testing of scaffolding components.

- NASC (National Access & Scaffolding Confederation) Guidance: Provides industry best practices and safety recommendations for scaffolding.

- Experience: 'How long have you been in business, and what experience do you have with projects like mine?'

- Licensing and Insurance: 'Are you fully licensed and insured, and can I see proof of coverage?'

- Safety Record: 'What are your safety procedures, and how do you ensure worker safety on the job site?'

- References: 'Can you provide references from previous clients?'

- Quotes and Costs: 'Can you provide a detailed quote that outlines all costs, including materials, labor, and any additional services?'

- Project Timeline: 'What is the estimated timeframe for scaffolding erection and dismantling?'

- Communication: 'How will you communicate with me throughout the project?'

How long does it take to erect scaffolding?

What are some tips for working safely on scaffolding?

What are the safety regulations for scaffolding in the USA?

What questions should I ask a scaffolding company before hiring them?

How long does it take to erect scaffolding?

- Size and Complexity: Larger, more intricate scaffolding structures will naturally take longer to assemble.

- Scaffolding Type: System scaffolding, with its pre-engineered components, can be erected faster than traditional tube and clamp scaffolding.

- Accessibility: Difficult site access or limited working space can prolong the erection process.

- Crew Size and Experience: The number and skill level of the scaffolding erectors will impact the speed of assembly.

What are some tips for working safely on scaffolding?

- Always Wear a Safety Harness: Connect your harness to a secure anchor point at all times to prevent falls.

- Keep Platforms Clear: Remove tools, materials, and debris to avoid tripping hazards.

- Never Overload the Scaffolding: Stay within the designated weight limits.

- Be Aware of Your Surroundings: Pay attention to power lines, moving equipment, and other potential hazards.

- Inspect Before Use: Check the scaffolding for any damage or defects before starting work.

- Communicate Clearly: Use hand signals and clear communication to coordinate with other workers.

- Follow Safety Training: Attend and understand all safety training provided by your employer or the scaffolding company.

What are the safety regulations for scaffolding in the USA?

- Work at Height Regulations 2005: Covers all work at height and outlines the need for risk assessments, competent erectors, and safe equipment.

- Construction (Design and Management) Regulations 2015 (CDM): Applies to construction projects and requires planning for scaffolding safety throughout the project lifecycle.

- British Standard BS EN 12811: Sets standards for the design, manufacture, and testing of scaffolding components.

- NASC (National Access & Scaffolding Confederation) Guidance: Provides industry best practices and safety recommendations for scaffolding.

What questions should I ask a scaffolding company before hiring them?

- Experience: 'How long have you been in business, and what experience do you have with projects like mine?'

- Licensing and Insurance: 'Are you fully licensed and insured, and can I see proof of coverage?'

- Safety Record: 'What are your safety procedures, and how do you ensure worker safety on the job site?'

- References: 'Can you provide references from previous clients?'

- Quotes and Costs: 'Can you provide a detailed quote that outlines all costs, including materials, labor, and any additional services?'

- Project Timeline: 'What is the estimated timeframe for scaffolding erection and dismantling?'

- Communication: 'How will you communicate with me throughout the project?'