Commercial Scaffolding Milwaukee

Top Commercial Scaffolding in Milwaukee

Receive 3 FREE Industrial Scaffolding quotes for your project today! Compare profiles, reviews, accreditations, portfolio, etc... and choose the best deal.

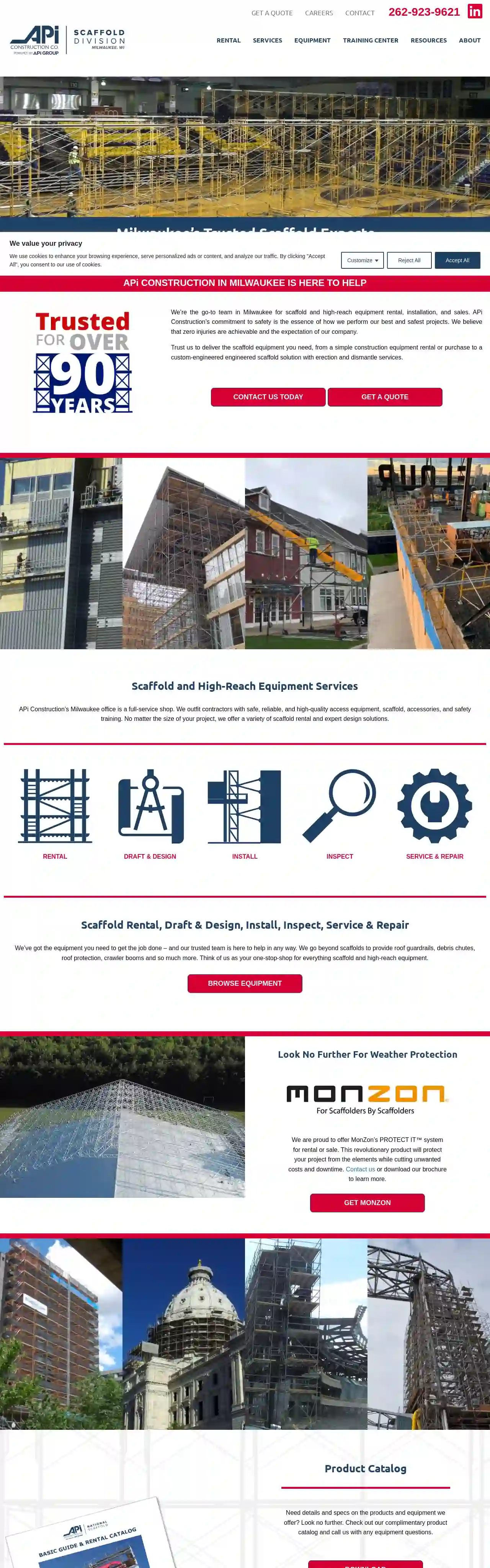

API Construction

51 reviews2725 S 163rd Street, New Berlin, 53151, USAPi Construction is a trusted scaffold and high-reach equipment expert in Milwaukee, Wisconsin. We provide safe, reliable, and high-quality access equipment, scaffold, accessories, and safety training for contractors. Our commitment to safety is the essence of how we perform our best and safest projects. We believe that zero injuries are achievable and the expectation of our company. We offer a variety of scaffold rental and expert design solutions, including custom-engineered scaffold solutions with erection and dismantle services. Our team of skilled scaffold engineers and designers provides total end-to-end support of your scaffold requirements, no matter the project scope. We are proud to be powered by the APi Group and are ready to serve your projects in Wisconsin and the surrounding area.

- Services

- Why Us?

- Accreditations

- Our Team

- Gallery

Get Quote

Badger Ladder LLC

4.637 reviewsMilwaukee, USBadger Ladder is a trusted supplier of scaffolding for sale, ladders, and pump jacks, with nearly 30 years of industry experience. Our scaffolding products offer customizable heights for easier access to difficult areas, and are built to last. We provide various types of scaffolding, including cross braces, stacking pins, and scaffold planks to meet all your project needs. Our scaffolding for sale online offers the advantages of powder-coat paint, preventing rust, and a cope-welded design for enhanced strength. Designed to meet the demands of any workload, our scaffolding is suitable for both interior and exterior use.

- Services

- Why Us?

- Gallery

Get Quote

Wisconsin Scaffolding

1Menomonee Falls, WI, N58 W14810 Shawn Circle, 53051, USContractors Access Equipment, Inc. (CAE) is a construction industry business specializing in scaffolding rental and installation throughout Wisconsin. Since 2001, CAE has worked hard to become an indispensable resource for customers. With specialized experience, multiple branch locations, and a diverse inventory of scaffold equipment, CAE can design and execute access solutions for almost any project environment. CAE provides the best scaffolding throughout Wisconsin, including Beloit, Janesville, Kenosha, Madison, Milwaukee, Pewaukee, Racine, and Waukesha.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

- Gallery

Get Quote

BrandSafway Industries Milwaukee

410 reviews1234 Industrial Drive, Milwaukee, 53203, USBrandSafway is a leading provider of access solutions, including scaffolding, aerial work platforms, and forming and shoring. With a strong commitment to safety, quality, and customer satisfaction, BrandSafway offers a wide range of services tailored to meet the unique needs of clients across various industries. Their team of experienced professionals works closely with clients to understand their requirements and deliver customized solutions that enhance efficiency and productivity. BrandSafway is dedicated to providing innovative access solutions that ensure safe and efficient project execution.

- Services

- Why Us?

- Accreditations

- Our Team

- Testimonials

Get Quote

Over 679+ Scaffolding Businesses onboarded

Our scaffolding contractors operate in Milwaukee and surrounding areas!

ScaffoldingHQ has curated and vetted Top Scaffolding Businesses arround Milwaukee. Find a top & trustworthy pro today.

Frequently Asked Questions About Commercial Scaffolding

- Steel: The most common material due to its strength, durability, and resistance to corrosion. It's suitable for most commercial applications.

- Aluminum: Lighter than steel, often preferred for smaller projects or where weight restrictions apply.

- Timber (Wood): Used for decking platforms and in some traditional scaffolding structures, but less common in modern commercial projects.

- Fiberglass: Used in specialized applications where electrical conductivity is a concern (e.g., near power lines).

- Experience: Look for a company with extensive experience in commercial scaffolding projects similar in scope and complexity to yours.

- Reputation: Check online reviews and testimonials to gauge their reliability, quality of work, and professionalism.

- Safety Record: Inquire about their safety protocols, training programs, and accident history.

- Licensing and Insurance: Verify they are fully licensed, insured, and bonded to protect you from liability.

- Capacity and Equipment: Ensure they have the resources, equipment, and expertise to handle your project's size and specifications.

- Pricing and Contracts: Obtain detailed quotes, compare pricing, and review contract terms carefully.

- Communication and Project Management: Choose a company that communicates clearly, is responsive to your needs, and has a well-defined project management process.

- Thorough Planning: Conduct detailed site surveys, engage qualified scaffolding engineers, and obtain necessary permits.

- Hiring Reputable Companies: Choose scaffolding companies with strong safety records, experienced erectors, and comprehensive safety programs.

- Comprehensive Training: Ensure all workers using the scaffolding receive adequate training on scaffolding safety, fall protection, and hazard identification.

- Regular Inspections: Conduct frequent inspections of the scaffolding by a competent person to identify and address any potential hazards.

- Enforcement of Safety Protocols: Strictly enforce safety rules on the job site, including the use of harnesses, hard hats, and other PPE.

- Clear Communication: Maintain open communication channels between the scaffolding company, contractors, and workers to address any safety concerns promptly.

- Emergency Preparedness: Develop and communicate clear emergency procedures in case of accidents.

- Mobile Elevated Work Platforms (MEWPs): Scissor lifts, boom lifts, and other MEWPs provide a mobile and versatile platform for reaching various heights.

- Mast Climbing Work Platforms (MCWPs): Ideal for high-rise buildings, offering a stable working platform that can be raised incrementally.

- Suspended Access Equipment: Ropes and harnesses used for specialized tasks like window cleaning or facade repairs, but with limitations on load capacity and movement.

What are some common scaffolding materials used in commercial projects?

How do I choose the right commercial scaffolding company?

How can I reduce the risk of scaffolding-related accidents on my commercial project?

What are some alternatives to traditional scaffolding for commercial projects?

What are some common scaffolding materials used in commercial projects?

- Steel: The most common material due to its strength, durability, and resistance to corrosion. It's suitable for most commercial applications.

- Aluminum: Lighter than steel, often preferred for smaller projects or where weight restrictions apply.

- Timber (Wood): Used for decking platforms and in some traditional scaffolding structures, but less common in modern commercial projects.

- Fiberglass: Used in specialized applications where electrical conductivity is a concern (e.g., near power lines).

How do I choose the right commercial scaffolding company?

- Experience: Look for a company with extensive experience in commercial scaffolding projects similar in scope and complexity to yours.

- Reputation: Check online reviews and testimonials to gauge their reliability, quality of work, and professionalism.

- Safety Record: Inquire about their safety protocols, training programs, and accident history.

- Licensing and Insurance: Verify they are fully licensed, insured, and bonded to protect you from liability.

- Capacity and Equipment: Ensure they have the resources, equipment, and expertise to handle your project's size and specifications.

- Pricing and Contracts: Obtain detailed quotes, compare pricing, and review contract terms carefully.

- Communication and Project Management: Choose a company that communicates clearly, is responsive to your needs, and has a well-defined project management process.

How can I reduce the risk of scaffolding-related accidents on my commercial project?

- Thorough Planning: Conduct detailed site surveys, engage qualified scaffolding engineers, and obtain necessary permits.

- Hiring Reputable Companies: Choose scaffolding companies with strong safety records, experienced erectors, and comprehensive safety programs.

- Comprehensive Training: Ensure all workers using the scaffolding receive adequate training on scaffolding safety, fall protection, and hazard identification.

- Regular Inspections: Conduct frequent inspections of the scaffolding by a competent person to identify and address any potential hazards.

- Enforcement of Safety Protocols: Strictly enforce safety rules on the job site, including the use of harnesses, hard hats, and other PPE.

- Clear Communication: Maintain open communication channels between the scaffolding company, contractors, and workers to address any safety concerns promptly.

- Emergency Preparedness: Develop and communicate clear emergency procedures in case of accidents.

What are some alternatives to traditional scaffolding for commercial projects?

- Mobile Elevated Work Platforms (MEWPs): Scissor lifts, boom lifts, and other MEWPs provide a mobile and versatile platform for reaching various heights.

- Mast Climbing Work Platforms (MCWPs): Ideal for high-rise buildings, offering a stable working platform that can be raised incrementally.

- Suspended Access Equipment: Ropes and harnesses used for specialized tasks like window cleaning or facade repairs, but with limitations on load capacity and movement.